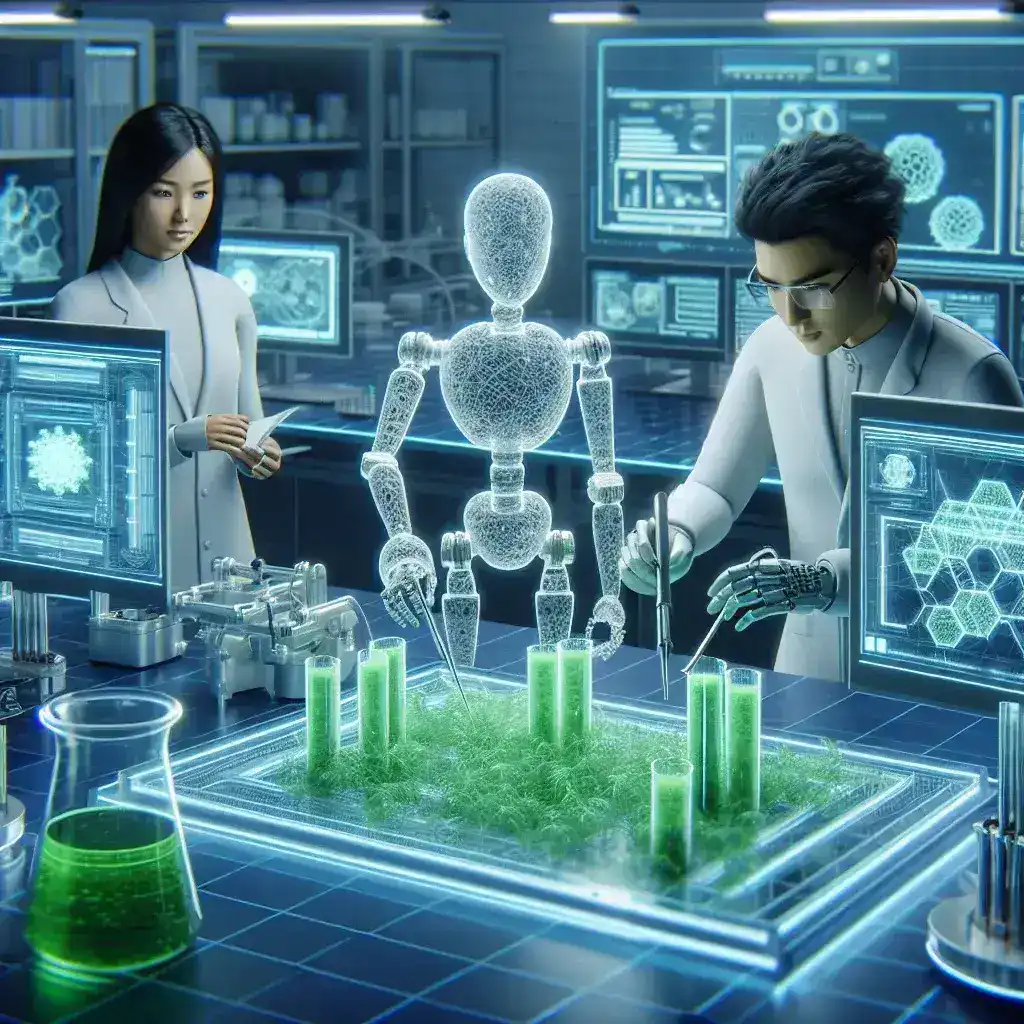

As the world grapples with the overwhelming issue of plastic pollution, researchers and innovators are turning to the latest technological advancements to seek solutions. Among these advancements, AI-enhanced lab robots are at the forefront, tirelessly working to uncover plant-based substitutes for plastics. This article delves into the capabilities of these remarkable robots, their implications for sustainability, and the future of material science.

The Rise of AI in Material Science

Artificial Intelligence (AI) has transformed various sectors, and material science is no exception. The combination of AI and robotics in labs has accelerated the innovation process, allowing researchers to explore and develop new materials at an unprecedented rate. By analyzing vast datasets, AI systems can identify patterns and predict the properties of new compounds, streamlining the discovery of alternatives to traditional plastics.

Understanding the Need for Alternatives

Plastic pollution is a pressing global crisis. According to recent studies, over 300 million tons of plastic are produced annually, with a significant portion ending up in oceans, landfills, and ecosystems. This has sparked a dire need for sustainable alternatives that not only perform similarly to conventional plastics but also mitigate environmental harm.

The Role of Lab Robots

AI-enhanced lab robots have revolutionized how researchers approach the search for plant-based materials. These robots are equipped with advanced sensors and computational power that enable them to conduct experiments autonomously. Some of their key functions include:

- High-throughput screening: Lab robots can test thousands of compounds simultaneously, significantly speeding up the research process.

- Data analysis: They analyze the results in real-time, providing immediate feedback and insights that drive further experimentation.

- Automated synthesis: These robots can synthesize new materials based on AI-generated hypotheses, creating a rapid prototyping environment.

How AI Enhances the Discovery Process

The integration of AI into lab robotics offers several advantages that enhance the discovery of plant-based substitutes:

1. Predictive Modeling

AI algorithms can predict the behavior and properties of new materials based on existing data. This allows researchers to focus on the most promising candidates, reducing time and resources spent on unviable options.

2. Machine Learning Capabilities

Through machine learning, AI systems can learn from previous experiments, improving their predictive accuracy and informing future experiments. The more data they process, the smarter they become, leading to more efficient discoveries.

3. Enhanced Efficiency

With robots carrying out repetitive and labor-intensive tasks, researchers can concentrate on higher-level thinking and creative problem-solving, improving overall productivity in labs.

Case Studies: Successful Discoveries

Several institutions and startups have successfully employed AI-enhanced lab robots to discover plant-based alternatives to plastics:

- NatureWorks: This company has utilized AI to optimize its production of Ingeo™, a biopolymer derived from renewable resources, significantly reducing its environmental footprint.

- Green Dot Bioplastics: Using AI algorithms, this company has developed a line of compostable bioplastics that perform comparably to traditional plastics.

- BioLogiQ: Their robots have helped in creating sustainable alternatives to plastic packaging, harnessing the power of natural resources.

The Future of Plant-Based Plastics

The ongoing advancements in AI and robotics signal a promising future for the development of plant-based substitutes. As technology continues to evolve, we can anticipate:

1. Increased Collaboration

Cross-disciplinary collaboration between AI experts, materials scientists, and environmentalists will accelerate innovation and create holistic solutions.

2. Commercial Viability

As lab discoveries translate into marketable products, businesses will begin to adopt these sustainable materials on a larger scale, driving a shift away from conventional plastics.

3. Global Impact

The widespread adoption of plant-based plastics can significantly reduce plastic pollution, contributing positively to global environmental efforts.

Challenges to Overcome

Despite the promising future, several challenges remain in the quest for viable plant-based substitutes:

- Cost of Production: Often, the production of bioplastics is more expensive than traditional plastics, which can deter widespread adoption.

- Performance Limitations: While many plant-based alternatives are being developed, achieving the same performance characteristics as traditional plastics remains a challenge.

- Consumer Awareness: Educating consumers on the benefits and availability of plant-based options is crucial for market acceptance.

Conclusion

AI-enhanced lab robots are pioneering the quest for plant-based substitutes for plastics, harnessing technology to combat one of the most significant environmental challenges of our time. By optimizing the discovery process and fostering innovation, these robots are not only reshaping the landscape of material science but also paving the way for a sustainable future. As we continue to navigate the complexities of sustainability, the collaboration between AI and robotics will undoubtedly play a crucial role in creating a cleaner, greener planet.