Surface Acoustic Wave (SAW) touchscreens are a sophisticated type of touch technology that use ultrasonic waves to detect touch input. These screens are known for their durability, clarity, and accuracy. So, what are the materials used in SAW touchscreens that make them so effective? This article dives deep into the components and materials that comprise SAW touchscreens and how they contribute to the technology’s performance.

Key Materials in SAW Touchscreens

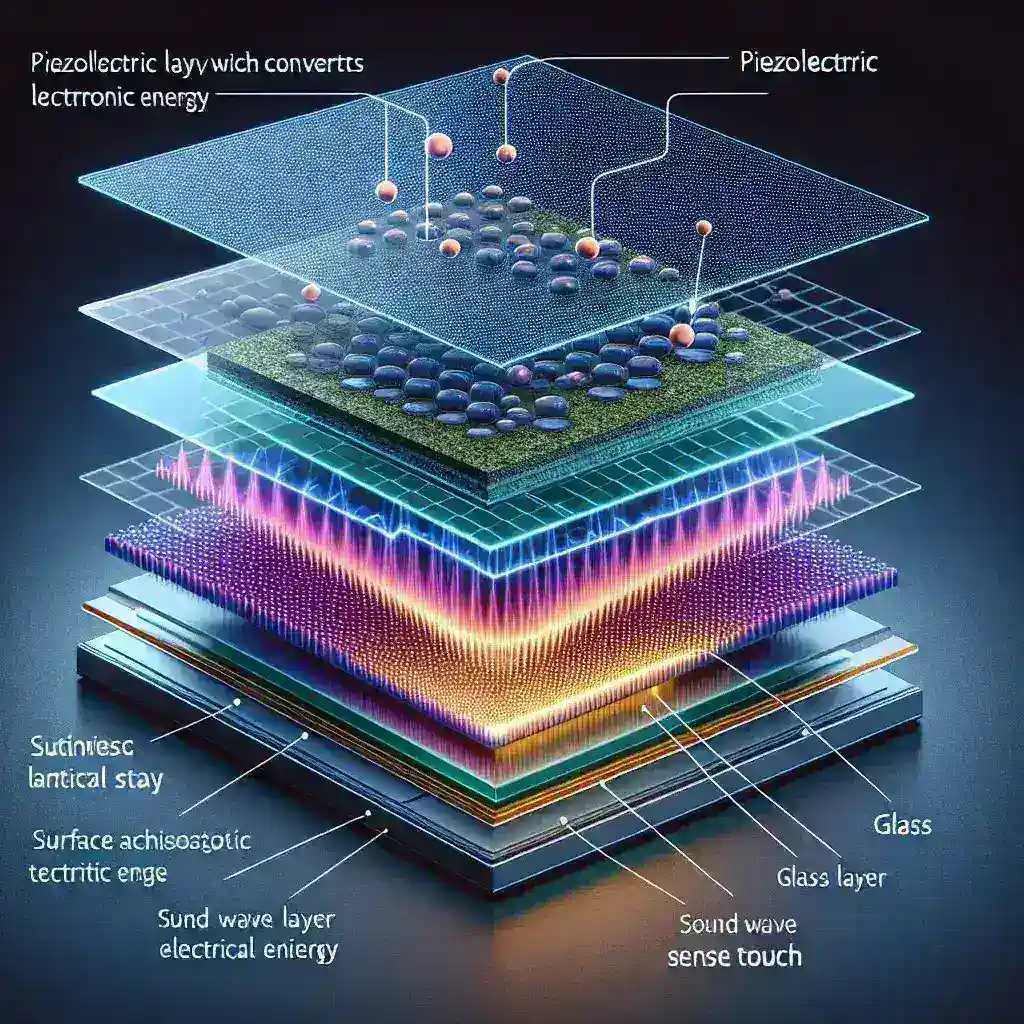

The primary materials used in SAW touchscreens include:

| Material | Function |

|---|---|

| Glass | Base material for the screen, providing a clear and durable surface. |

| Piezoelectric Transducers | Generate and receive ultrasonic waves. |

| Reflective Stripes | Guide the ultrasonic waves across the screen. |

1. Glass

Glass is the most prevalent material used in SAW touchscreens. The reasons for using glass are manifold:

- Clarity: Glass offers superior optical clarity, which is crucial for display quality.

- Durability: Glass is highly resistant to scratches and environmental factors.

- Sensitivity: The material’s physical properties enable accurate touch detection.

The glass used in SAW touchscreens often comes with a protective coating to further enhance its durability and touch sensitivity.

2. Piezoelectric Transducers

Piezoelectric transducers are another critical component in SAW touchscreens. These transducers have dual roles:

- Ultrasonic Wave Generation: They convert electrical energy into ultrasonic waves.

- Ultrasonic Wave Reception: On receiving the waves, they convert them back into electrical signals for processing.

The transducers are typically made from piezoelectric materials like quartz or ceramic, which are efficient in energy conversion and provide high sensitivity.

3. Reflective Stripes

Reflective stripes are integrated into the screen to direct the ultrasonic waves across its surface. These stripes are usually made from metallic materials and are carefully engineered to ensure minimal energy loss and maximum wave precision. The stripes reflect the ultrasonic waves in precise patterns, enabling accurate touch detection.

Additional Coatings and Layers

Beyond the primary materials, SAW touchscreens also have various coatings and layers that enhance functionality:

Anti-Reflective Coating

This coating minimizes glare, improving screen visibility in different lighting conditions. It is especially useful in outdoor environments.

Protective Layer

Some SAW touchscreens include a protective outer layer to guard against physical damage. This layer is usually made from durable plastics or other resilient materials.

Conductive Film

In some advanced SAW touchscreens, a conductive film is used to improve touch sensitivity and accuracy. This film can be made from metals like indium tin oxide (ITO).

How SAW Touchscreens Work

Understanding the materials is essential, but it’s equally important to understand how a SAW touchscreen operates. Here’s a simplified overview of the working principle:

Generation and Reflection of Ultrasonic Waves

The process begins with the piezoelectric transducers generating ultrasonic waves. These waves travel across the surface of the glass screen, guided by reflective stripes.

Detection of Touch

When a user touches the screen, the ultrasonic waves are disrupted. The piezoelectric transducers detect this disruption by measuring changes in the wave patterns and convert these changes into electrical signals.

Signal Processing

The electrical signals are then sent to a touch controller, which interprets them to determine the exact location of the touch. This data is subsequently used to execute the corresponding actions on the device.

Advantages of SAW Touchscreens

SAW touchscreens offer several benefits that make them a preferred choice in various applications:

High Durability

The glass surface is resistant to scratches and external damage, making SAW touchscreens suitable for high-traffic environments.

Excellent Clarity

The optical clarity of glass ensures that the display’s visual quality is not compromised.

High Sensitivity

SAW touchscreens are highly responsive, capable of accurately detecting even light touches.

Applications of SAW Touchscreens

Given their advantages, SAW touchscreens are employed in diverse sectors:

Public Information Kiosks

Durability and clarity make them ideal for public information kiosks.

Industrial Control Panels

High sensitivity and durability are essential in industrial environments for reliable operation.

ATMs and Banking Terminals

The tough, vandal-resistant glass is perfect for ATM and banking terminal displays.

Medical Devices

Clarity and precision are critical for medical touchscreens used in diagnostics and operations.

Conclusion

SAW touchscreens leverage advanced materials like glass, piezoelectric transducers, and reflective stripes to deliver durable, high-quality, and sensitive touch interfaces. Their unique construction and working principle make them suitable for various demanding applications, providing both reliability and performance. Understanding these materials helps appreciate the technology behind SAW touchscreens and their continued relevance in the touch technology landscape.